- Compact spool valve with threaded port connections

- all exhaust ports are pipable, providing better protection against harsh environments

- standard manual operated

- DIN, Watertight and explosionproof solenoids

- single and dual solenoid constructions available mountable in any position

- unique design combines hard T-seals and flexible o-rings, provides bubble-tight shutoff, resistance to dirt and multimillion cycle life controlling air or inert gas

- low power and intrinsically safe constructions available

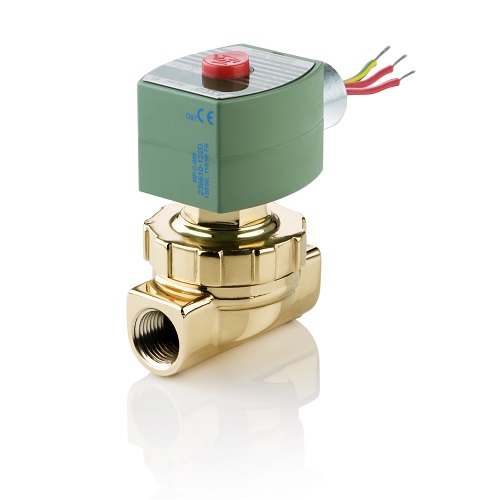

Solenoid Valve - 3 Way: 3/2 - 4 Way: 5/2, 5/3 - Spool Valve - ASCO Series 551

Solenoid valves for dust-collector systems

There are a variety of manufacturers making valves, actuators and other automation components that control the flow of compressed air through industrial dust collector systems.

What makes ASCO different is its unique combination of quality, performance and value with quick shipment for ensured availability as well as consistent technical support and service for easy assembly, reliable operation and efficient maintenance.

For decades, we’ve been a leading supplier to original equipment manufacturers (OEMs) and to end users of dust collector systems in a wide range of industries, including the following:

- Concrete Processing

- Grain, Agriculture and Feed

- Metal Working (Abrasive Blasting)

- Food Processing

- Foundries

- Life Science

ASCO provides the world’s best-supported automation for dust collector systems. Our ultra-reliable valves, switches, actuators header tanks and other components come with ensured availability and localised support that no other manufacturer can match.

The ASCO Valve Dust Collector Series are high-flow fast-opening 2-way valves, pilot valves, pilot valve enclosures, and bulkhead fittings that have been specially designed for use in dust collector systems.

The solenoid is an electromagnetic part of a valve, comprised of a coil, core tube, core and enclosure. The ASCO RedHat brand offers the world’s largest selection of 2-way, 3-way and 4-way solenoid valves, designed to handle the most demanding fluid control applications.

ASCO’s 2-Way solenoid valves have one inlet and one outlet, and are used to permit and shut off fluid flow. The two types of operations are Normally Closed (NC) and Normally Open (NO). Two types of constructions apply to 2-way solenoid valves, which are direct acting and internally piloted.

With Direct acting constructions, the solenoid is energized, the core directly opens the orifice of a Normally Closed valve or closes the orifice in a Normally Open Valve. The valve will operate at pressures from 0 psi to its rated maximum.

Internally piloted constructions use line pressure to assist operation. When the coil is de-energized (on a Normally Closed Valve), the pilot orifice is closed and line pressure is applied to the top of the piston or diaphragm through the bleed orifice, closing the valve.

ASCO 3-Way Solenoid Valves have three pipe connections and two orifices. When one orifice is open, the other is closed and vice versa. They are commonly used to alternately apply pressure to an exhaust pressure from a valve actuator or a single acting cylinder. These valves can be normally closed, normally open or universal.

ASCO 4-Way Solenoid Valves have four or five pipe connections, commonly called ports. One pressure inlet, two cylinder ports providing pressure to the double acting cylinder or actuator and one or two outlets to exhaust pressure from the cylinders. They have three types of construction, single solenoid, dual solenoid or single air operator.

General Service Solenoid Valves